- admin

- March 31, 2024

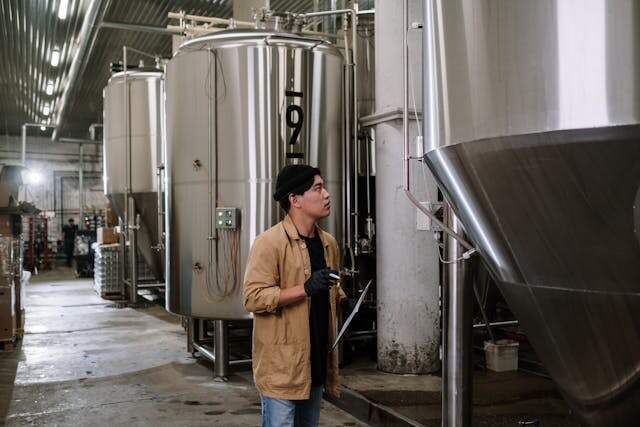

Unveiling the Crucial Role of Industrial Tanks in Manufacturing Excellence

In the realm of manufacturing, where precision, efficiency, and safety are paramount, industrial tanks play a pivotal role that often goes unnoticed. From storing raw materials to facilitating intricate chemical reactions, these tanks form the backbone of numerous manufacturing processes across industries. Understanding their significance sheds light on their indispensable role in ensuring seamless operations and product quality.

Storage and Management of Raw Materials

Industrial tanks serve as the primary storage units for raw materials used in manufacturing processes. Whether it’s liquids, gases, or solids, these tanks provide a secure and controlled environment for storing materials in bulk quantities. This aspect is particularly crucial for industries dealing with chemical , petroleum, pharmaceuticals, and food processing, where maintaining the integrity of raw materials is essential for product quality and safety.

Facilitating Chemical Reactions and Processes in Industrial Tanks in Manufacturing

Manufacturing often needs specific conditions for chemical reactions to happen well and without danger. Industrial tanks are built to handle strong chemicals and create the right settings for these reactions. They help in mixing, blending, fermentation, and other chemical processes by controlling factors like temperature, pressure, and pH. This leads to the expected results.

Waste Management and Environmental Compliance

Good waste management is very important for being responsible in manufacturing. Industrial tanks are really important for collecting, treating, and getting rid of different waste from making things. They help with things like wastewater, dangerous chemicals, and leftovers. These tanks make sure waste is separated, treated, and thrown away safely, which helps protect the environment and follow rules.

Supply Chain Optimization in Industrial Tanks in Manufacturing

Industrial tanks contribute significantly to optimizing the supply chain in manufacturing operations. By storing raw materials in bulk quantities, they enable manufacturers to leverage economies of scale, reducing procurement costs and ensuring uninterrupted production schedules. Moreover, strategically located tanks can streamline logistics and distribution processes, minimizing transportation costs and lead times associated with frequent material replenishments.

Ensuring Operational Reliability and Safety

In any manufacturing facility, operational reliability and safety are non-negotiable aspects. Industrial tanks are engineered and maintained to meet stringent safety standards and regulatory requirements. Robust construction, leak detection systems, corrosion-resistant materials, and routine inspections ensure that these tanks operate safely and reliably, minimizing the risk of accidents, spills, and environmental hazards.

Conclusion

In essence, industrial tanks are not just storage vessels; they are indispensable assets that form the foundation of modern manufacturing processes. From storing raw materials to facilitating complex chemical reactions, managing waste, optimizing supply chains, and ensuring operational safety, these tanks play multifaceted roles that are essential for the success and sustainability of manufacturing operations. Understanding their importance underscores the need for investing in quality tank solutions and implementing best practices in their design, operation, and maintenance.

- Crucial Role of Industrial Tanks in Manufacturing

- Industrial Tanks in Manufacturing

Category

- Above Ground Fuel Tanks

- Above Ground Gas Storage Tank

- Above Ground Storage Tanks

- Above Ground Water Storage Tanks

- Agricultural Tanks

- Chemical storage Tanks

- Diesel Fuel Storage Tanks

- Diesel Storage Tanks

- Exernal FloatingRoof Tanks

- Farm Water Tank

- Fiberglass Oil Tanks

- Fiberglass Septic Tanks

- Fiberglass Tanks

- Fiberglass Underground Fuel Storage Tanks

- Field Erected Tanks

- Floating Roof Tank

- Food and Beverage Tanks

- Fuel tank

- Industrial Chemical Storage Tanks

- Industrial Gas Tanks

- Industrial Hot Water Storage Tanks

- industrial hot water tank

- Industrial Plastic Tanks

- Industrial Storage Tanks

- Industrial Tank heating pads

- industrial tanks

- Natural gas

- Natural gas vs Propane

- oil storage tank

- Oil Storage Tanks

- Peracitic Acid

- Petroleum Tanks

- Residential gasoline storage tanks

- Residential Water Storage Tanks

- Sodium Hydroxide Storage Requirements

- Sodium Hypochlorite Storage Tanks

- Steel Storage Tanks

- storage tank failure prevention

- Storage Tanks

- Sulfuric Acid Tanks

- Uncategorized

- UnderGround Storage Tanks

- Waste water tank

- Water Storage Tanks

Tank Size Calculator

Tank Size Calculator